Africa-Press – Sierra-Leone. In a pioneering move toward sustainable innovation, Leotech has successfully implemented a capacity-building workshop titled “The Circular Economy Pathway to Additive Manufacturing (Waste for 3D Printing)” in collaboration with Freetown Innovation Labs and Skills Pool.

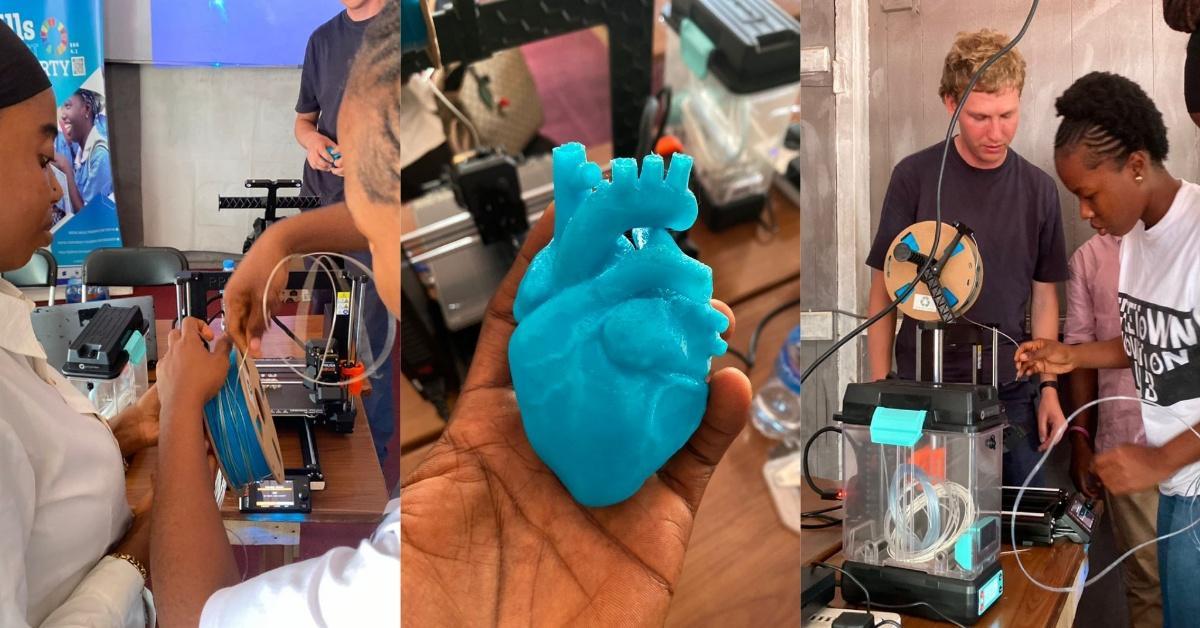

The workshop first of its kind in Sierra Leone trained eight staff volunteers from the three institutions, equipping them with practical skills in converting waste plastic bottles into 3D printing filament, computer-aided design (CAD), additive manufacturing (3D printing), and business model development within the circular economy framework.

The initiative comes at a time when Sierra Leone is grappling with serious plastic pollution challenges. Freetown alone generates hundreds of tons of plastic waste annually, with less than 15% being recycled or reused. This results in indiscriminate dumping, beach pollution, flooding, and environmental degradation. The workshop aimed to flip this problem into opportunity transforming waste into value through technology.

“This wasn’t just a training; it was a journey from waste to value,” said Alfred Mbayoh, CEO of Leotech, during the opening session. “We are tackling plastic pollution while building a sustainable local supply chain for 3D printing filament something that’s long overdue in Sierra Leone.”

Additive Manufacturing, commonly known as 3D printing, is a cutting-edge technology that enables the rapid transformation of digital designs into tangible products. Despite its global relevance, the technology has seen limited adoption in Sierra Leone due to high import costs for 3D printing filaments and a scarcity of local expertise.

The workshop was led by Danish design engineer Rasmus Emil Tofthoj, who brought his extensive knowledge in product design and additive manufacturing. Leotech provided the training facility and local CAD experts, while Freetown Innovation Labs and Skills Pool contributed business development expertise and hands-on training in converting plastic waste into usable filament.

Mohamed Kamara, Managing Director of Freetown Innovation Labs, guided participants on how to build viable business models around recycled plastic products. Representing Skills Pool, Shamsu Koroma demonstrated practical methods for processing waste plastic into filament, a critical component of 3D printing technology.

Participants emerged from the program with sharpened skills in sustainable product development and a renewed sense of purpose in advancing local innovation. The workshop highlighted how the circular economy can empower youth, reduce environmental waste, and stimulate entrepreneurship.

The consortium behind this initiative has pledged to scale up the project and is actively seeking support and partnerships from government bodies, private sector players, and development organizations.

“This is just the beginning,” said Alfred Mbayoh. “We’re not only reducing plastic waste but also laying the groundwork for a new generation of local innovators who can compete globally using sustainable technologies.”

For More News And Analysis About Sierra-Leone Follow Africa-Press